Salt-glaze

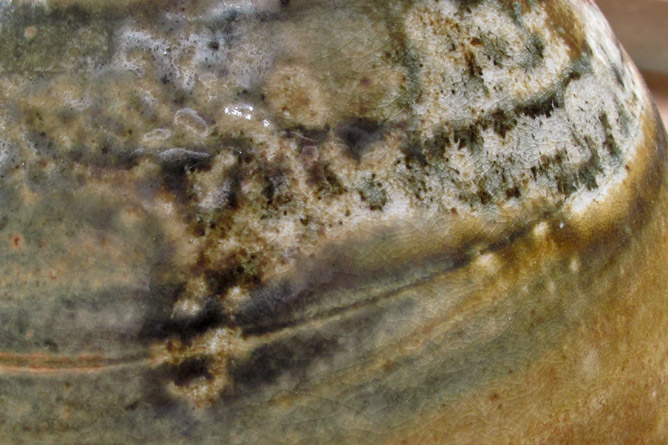

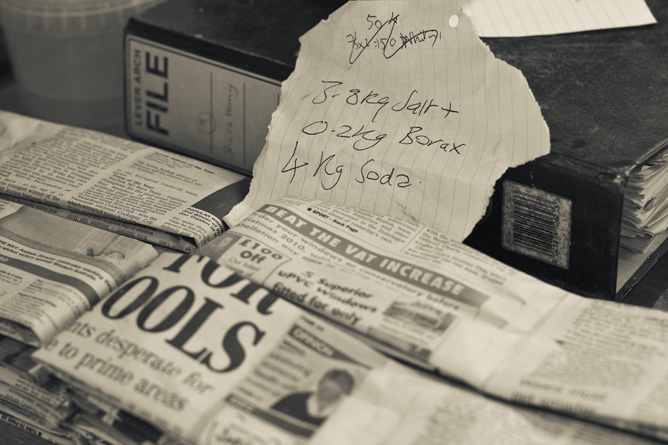

Salt-glaze is the dynamic process I use to decorate and glaze my pots. Common salt along with sodium carbonate (washing soda), is added during kiln firing to the fireboxes. The chamber at this point is white hot, approximately 1200ºC. The heat of the firebox forces the salts to vaporise into their gaseous elements. It is the sodium element which combines with the clay itself and any slips applied to it, to create a range of beautiful and serendipitous glazes.

The origins of this salt-glaze process are somewhat uncertain and undocumented. The very first salt-glazed stonewares appear to have been made in the Rhineland, Germany during late 13th or early 14th centuries. It seems probable that a group of potters firing and then unpacking their kiln, noticed that a new source of timber yielded a thin glazed surface to the otherwise bare clay, and that this timber for whatever original purpose was impregnated with common salt. Here began several hundreds of years of inspiration and exploration for peasants, potters and artists alike.

If you are interested in further reading on salt-glazing, please view publications under CV.

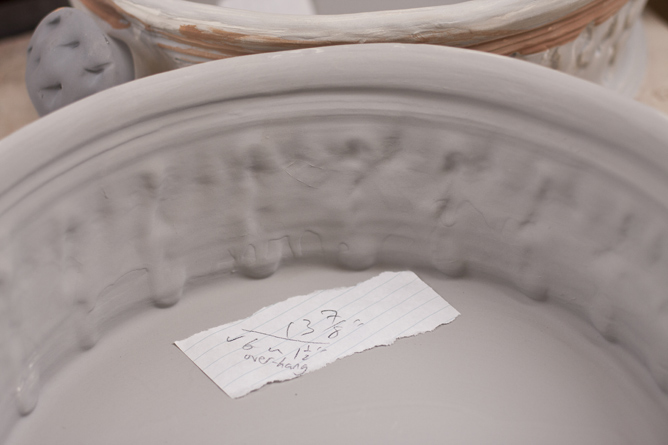

This slideshow illustrates and describes the range of processes associated with salt-glazing