Clay

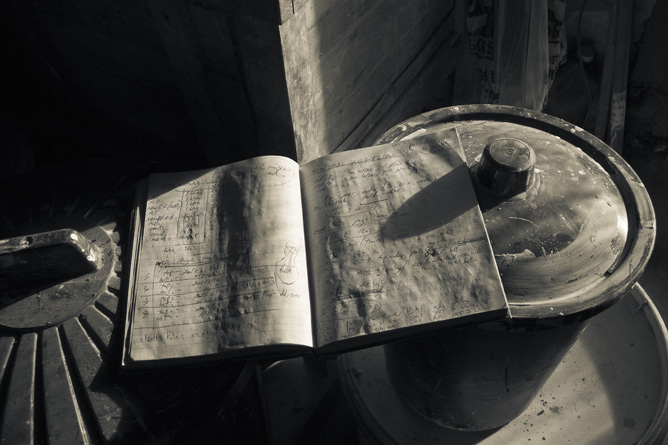

The magic of making and firing pots begins here, with the material itself. Mud! I use a couple of commercial clays, including Limoges porcelain. However, my main stoneware throwing clays are blended and processed from dry powdered ingredients on site. This process requires considerable space and some basic equipment, and we are lucky to enjoy both at the Wobage studios.

The various clays, along with other associated ingredients, are bought and stored in bulk and made up as required. The process of bringing these raw materials to a useable plastic material, is time consuming and physical work, but I love it! It is a great luxury on several counts, and an integral and important part of my creative work. It allows me the freedom to alter recipes, to suit the type and size of pots I am making. Oven ware clay, or larger pots for example, demand a different clay to smaller pots like mugs and jugs. This facility to creatively play with clay recipes, is also the foundation for a complicity of other process, which revolves around the fired colour and surface quality of the pots.

This slideshow illustrates and describes the process of making dry powder into plastic clay.